How the suspension works, how it has evolved over the years, and where the design of suspension will go in the future.

When people think about car performance, words like zero horsepower, torque and acceleration from zero to one hundred usually come to mind. But if the driver can not control the car, all the power generated by the engine is useless. For this reason, automotive engineers have turned their attention to the suspension almost as soon as they acquired the technology of four-stroke internal combustion engines.

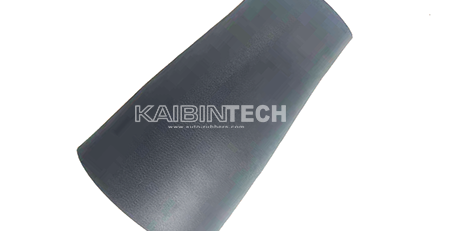

airmatic suspension bag for Mercedes Benz W213 X253 W257

The job of the car’s suspension is to maximize the friction between the tires and the road surface, to provide stable steering, good steering and to ensure that the occupants are comfortable. In this article, we explore how the suspension works, how it has evolved over the years, and where the design of suspension will go in the future.

If the roads were perfectly smooth and without any tampering, we would not need a suspension. But the roads are far from smooth. Even newly paved roads have minor imperfections that can affect car wheels. These imperfections apply force to the wheels, and according to Newton’s laws of motion, all forces have direction and magnitude. A bump causes the wheel to rise and fall vertically on the road surface. Of course, the force depends on the size of the bump. At the same time, the car’s wheel also gains a vertical acceleration when it crosses the surface.

Without an interfering system, all the vertical energy of the wheel is transferred to the chassis moving in the same direction. In such cases, it is possible for the wheels to come off the road completely and then, under gravity, to hit the road surface again. What you need is a system that absorbs the energy of the wheel (which has vertical acceleration) as it passes through the bump, allowing the chassis and body to move easily.

The study of forces in a moving vehicle is called vehicle dynamics, and to better understand the need for a suspension, it is necessary to know some concepts in the first place. Most car engineers look at the dynamics of a moving car from two perspectives:

Riding – The car’s ability to smoothly cross a bumpy road.

Steering wheel – car safety in acceleration, braking and in turns and turns.

air suspension strut repair kit 4E0616001 rear left Audi A8 D3 4E

These two characteristics can be explained in depth in three important areas – road insulation, road maintenance and bolts. The following table describes these components and how engineers try to solve these problems, individually and depending on their type:

A car’s suspension, with all its various components, provides the basis for all of these solutions. Let’s look at parts of a standard suspension. We start with the chassis and go down in sequence to the specific components that make up the suspension.

Chassis:

A car’s suspension is actually part of the chassis, which includes all the important systems under the body.

These include the following sections:

Chassis – A structural and load-bearing component that carries the car’s motorized body, thus being supported by the suspension.

Solenoid Valve Block for W251 E-Class W212 S212 AirMATIC Suspension Compressor.

Suspension – A weight-bearing body that absorbs and reduces shock and pressure and controls tire contact.

Steering system – a mechanism that enables the driver to steer and steer the vehicle.

Wheels and tires – components that allow the car to move by colliding (friction) with the road surface.

So suspension is one of the main systems in the car.

With this in mind, it’s time to pay attention to the three basic components of any suspension: springs, shock absorbers and surge arresters.

Springs:

Today’s spring systems are based on one of four general designs:

Torsion springs are the most common type of spring and are essentially a rigid metal rod that wraps around an axis. The screws open and close to make the wheels more attractive.

Mercedes Benz W166 front Air Spring Suspension Shock Absorber Repair Kits

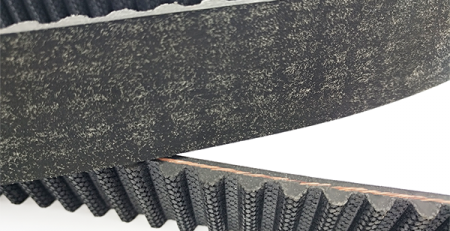

Flat springs – This type of spring is made up of different layers of metal that are joined together to act as a unit. Flat springs were first used in horse-drawn carriages and were used on most American cars until 1985. They are still used on most trucks and trucks today.

Torsion rods – Torsion rods use the torsion properties of a steel rod to create the same performance as a torsion spring. The way it works is that one end of the rod is hooked and attached to the car body. The other end is attached to a stern that acts as a lever that moves at a 90 ز angle to the torsion bar. When the wheel strikes a bump, the vertical motion is transmitted to the stern and then, during the leveling operation, to the torsion bar. The torsion bar then wraps around its axis to create a spring force. European automakers made extensive use of the system, as did the United States, Packard, and Chrysler during the 1950s and 1960s.

Pneumatic springs – The pneumatic spring, which consists of an air cylinder chamber, is located between the wheel and the car body, and uses air compression properties to prevent wheel vibrations. Its design is more than a century old and can be found in horse-drawn carriages. Air springs at that time were made of air bags full of air, very similar to airbags; In 1930, leather-molded air springs replaced these bags.

Steel Clamps Rings for Crimping Air Suspension Rubber Sleeve Bladder

Given the location of the springs in the car – which is between the wheels and the body – engineers often find it appropriate to talk about suspended mass and non-suspended mass (= mass that comes in contact with the road).

Springs: Suspended and non-suspended mass

Suspended mass is the mass of the vehicle on the springs, while suspended mass is defined separately as the mass between the road and the springs of the suspension. Spring dryness affects the reaction of the suspended mass while driving. Cars with a weak suspension mass, such as aristocratic cars (such as the Lincoln City Car), can easily digest bumps and provide an extremely smooth and comfortable ride; However, such a car suffers from diving and sitting, while braking and accelerating, and at the corners and turns, it shows a greater tendency to experience waves or torsion of the body. Cars with hard springs, such as sports cars (such as the Mazda Miata), are more violent than bumpy roads. But this type of car minimizes the movement of the body; And that means they have the ability to ride like crazy, even at the corners.

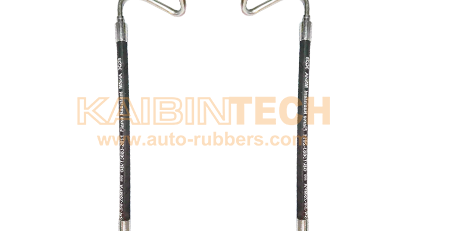

Mercedes W164 W251 Shock Absorber Sensor Cable Electronic Line

So while springs themselves seem like simple parts, designing and applying them to a car to balance passenger comfort and car control is a complex process. And to complicate matters, the springs alone cannot provide a perfectly smooth ride. Why? Because they are excellent at absorbing energy, but they are not good at releasing it. Other parts are needed as shock absorbers to do this well.