How to repair and maintain automobile shock absorbers?

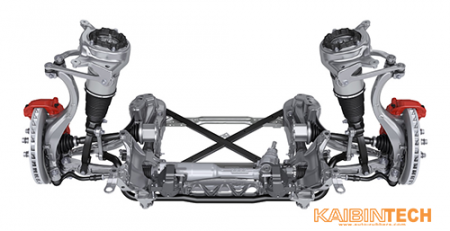

In order to quickly attenuate the vibration of the frame and the body, and improve the ride comfort and comfort of the car, the car suspension system is generally equipped with shock absorbers. At present, the two-way-acting cylinder shock absorber is widely used in automobiles.

The shock absorber is a vulnerable part during the use of the car. The working quality of the shock absorber will directly affect the smoothness of the car and the life of other parts. Therefore, we should keep the shock absorber in good working condition. The following methods are used to check whether the shock absorber is working well.

Make the car stop after driving 10km on the road with poor road conditions and touch the shock absorber shell with your hands. If it is not hot enough, it means that there is no resistance inside the shock absorber and the shock absorber does not work. At this time, you can add appropriate lubricating oil, and then perform the test. If the outer shell is hot, the shock absorber is short of oil, and enough oil should be added; otherwise, the shock absorber has failed; press the bumper firmly and then loosen it. If the car jumps 2 to 3 times, it means that the shock absorber is working well; when the car is driving slowly and braking urgently, if the car vibrates severely, it means that the shock absorber has a problem; remove the shock absorber and stand it upright. Clamp the lower connecting ring on the vise, and pull the damping rod several times. At this time, there should be stable resistance. The resistance of pulling upwards should be greater than the resistance of pushing downwards, such as unstable resistance or no resistance. It may be due to lack of oil inside the shock absorber or damage to valve parts. Repair or replacement parts should be carried out.

shock absorber for Mercedes Maybach 57 62 2002-2013 Left Right Front air suspension

After confirming that there is a problem or failure of the shock absorber, you should first check whether the shock absorber is leaking or has traces of old oil leakage.

The oil seal washer and sealing washer are broken and damaged, and the oil storage cylinder head nut is loose. It may be that the oil seal and sealing gasket are damaged and invalid. Replace with new seals. If the oil leakage still cannot be eliminated, pull out the shock absorber. If you feel a hairpin or change in weight, check whether the gap between the piston and the cylinder is too large, whether the piston connecting rod of the shock absorber is bent, and whether the piston connecting rod is bent. Whether there are scratches or pull marks on the surface and cylinder.

If there is no oil leakage from the shock absorber, check the shock absorber connecting pin, connecting rod, connecting hole, rubber, bushing, etc. for damage, desoldering, cracking or falling off. If the above inspection is normal, the shock absorber should be further disassembled to check whether the matching gap between the piston and the cylinder is too large, whether the cylinder is strained, whether the valve is well sealed, whether the valve clack and the valve seat are tightly attached, and whether Whether the extension spring of the vibrator is too soft or broken, it should be repaired by grinding or replacing parts according to the situation.

Air Spring Suspension Strut Repair Part shock core for Audi A8

In addition, the shock absorber may have noise failure in actual use. This is mainly due to the shock of the shock absorber and the leaf spring, the frame or the axle, the damage or fall of the rubber pad, and the deformation of the shock absorber dust tube. If it is caused by insufficient or other reasons, the cause shall be found out and repaired.

After the shock absorber is inspected and repaired, the performance test should be carried out on a special test bench. When the resistance frequency is 100±1mm, the resistance of the extension stroke and compression stroke should meet the requirements, indicating that the shock absorber is basically normal.